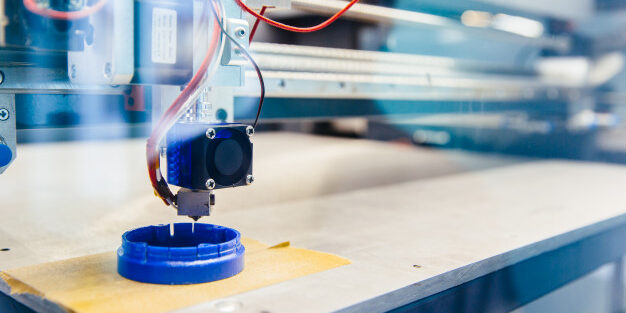

3D Printing is a printer that can build a 3-dimensional object. From Bugatti to Adidas, 3D printing has already touched these industries with its technology. 3D printing involves both the design process as well as the manufacturing process.

In collaboration with 3D printing leader Carbon, Adidas produced a limited-edition shoe with a durable and sleek 3D printed sole. The shoe was a success. It hints the potential 3D printing has in the world of fashion.

With a market size well over 10 billion, the world of 3D printing can grow by nearly 23.5% each year for the next five years (Source: 3D Hub). Since its inception (30 years ago), 3D printing advanced and grew a lot.

As mentioned in 3D Hubs’ 3D Printing Trends 2019 report, “The most significant change in 2018 was the evolution of our perception of the technology. 3D printing isn’t just for prototyping anymore; Additive is now a viable method of manufacturing.”

3D printing is everywhere. Jumping into the 3D Hubs report again, 65% of demand for 3D printing tech derives itself from engineers. They work in the development of industrial, electrical, or consumer goods.

Gartner Research estimated that in 2019, nearly 5.7 million 3D printers will ship annually. It estimated 500,000 printers in 2016. One reason for this exponential growth is that 3D printing facilitates complex designs. You cannot produce hard designs with conventional manufacturing technologies.

3D printing has matured over the past five years. Costs have come down significantly. The production of low-volume and complex parts via 3D printing is economically viable.

3D printing serves two functions across its wide range of industries: prototype and additive manufacturing.

As a prototyping solution, 3D printing accelerates product development. 3D printing for prototyping drastically speeds up the design process. It offers low-cost and functional prototypes. It also gives widely accessible solutions for companies of all sizes.

As a manufacturing technology, it helps in the production of end-use parts. Companies are using the technology for things like mass customization, on-demand production. They use it for distributed manufacturing.

3D printing has become popular. However, just like any other technology, there are advantages and disadvantages.

ADVANTAGES

- Customization:

It is an advantage in 3D printing. One can print any design. The complexity does not matter.

The Daimler Group conjunction with Mercedes Benz has found a way to 3D print spare parts for highly sought after Mercedes-Benz classics like the elegant 300 SL Coupé or the SL Roadster. Mercedes was able to take a decade-old designs and sketches and breathe new life into them. It printed the needed parts in a host of metal materials.

- Constant Prototyping and Increased Productivity

3D printing enables quick production with a high number of prototypes. It also allows a small-scale version of the real object in less time than using conventional methods. It helps designers to improve their prototypes. It avoids design flaws that may affect the quality of the product.

Slowly but surely, companies are emerging around the world. Companies hold the promise of creating homes. Companies build at a fraction of the cost and time.

Dubbed the Office of the Future, the project is part of Dubai’s big strategy of using 3D printing. It is to improve people’s lives. The printer is 20 feet high, 120 feet long and 40 feet wide. The 3D printing used for the office building not only helped cut labor costs by 50% but only took 17 days to print.

- Affordability

The initial cost for setting up a 3D printing facility is high. However, it is much cheaper compared to labor costs and manufacturing costs while using the conventional way.

- Storage

Traditional manufacturing produces additional products. The products that you probably know you will need. Thus, storage problems arise. You can print 3D printing technology products anytime. Thus excess products are eliminated. No storage cost is required.

- Employment Opportunities

The widespread use of 3D printing technology will increase the demand for engineers. Engineers are needed to design and build these printers. Technicians are skilled at troubleshooting and maintenance. Designers design blueprints for products. Thus more jobs will be created.

- Health Care

3D printing can manufacture customizable human body parts and organs. It is called Bioprinting. For now, this is just experimental. But there is potential. This breakthrough will address the shortage of organ donors.

Implanting 3D printed organs may seem unreal. But Prellis Biologics can assure that it is a real possibility soon. As part of the MBC Biologic incubator, the small team has made viable steps toward 3D printing hearts, livers, kidneys, and lungs.

DISADVANTAGES

- Decrease in Manufacturing Jobs

There will be a decrease in manufacturing jobs. It will affect the economy of countries that rely on a large number of low skill jobs.

- Limited Size

3D printers create a limited size of objects. However, soon 3D printing can create large items such as architectural structures.

- Limited Raw Materials

3D printers can work up to 100 different raw materials. Creating products that use more raw materials are still under development.

- Violation of Copyrights

Another disadvantage of 3D printing is that the service makes it easy for counterfeiting products. It will become more common. Tracing the source of the counterfeited items will be nearly impossible. Many copyright holders will have a hard time protecting their rights. Businesses producing unique products will suffer.

- Production of Dangerous Items

3D printers can create plastic knives, guns, and any other hazardous objects. It makes it easier for terrorists and criminals to bring a weapon without being detected.

Like!! Really appreciate you sharing this blog post. Really thank you! Keep writing.